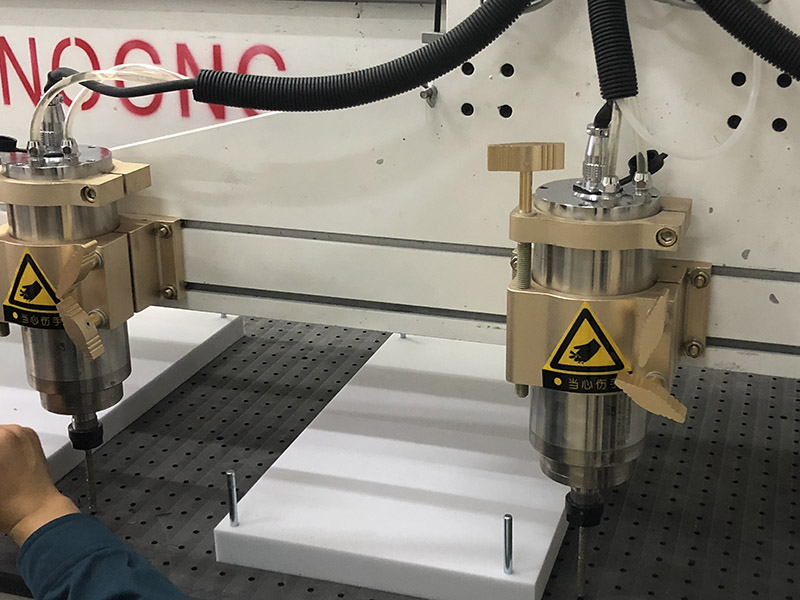

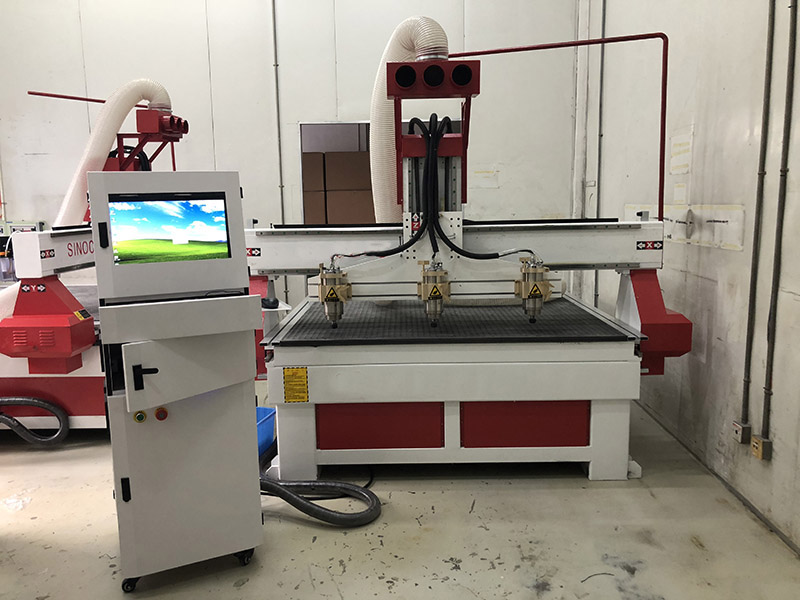

The series of multi-head small-format engraving machines meets the needs of small-format engraving production, and is a high-efficiency model series.

It is very stable at normal cutting speeds. The disadvantage is that the flexibility of tool setting is slightly less than that of independent head models.

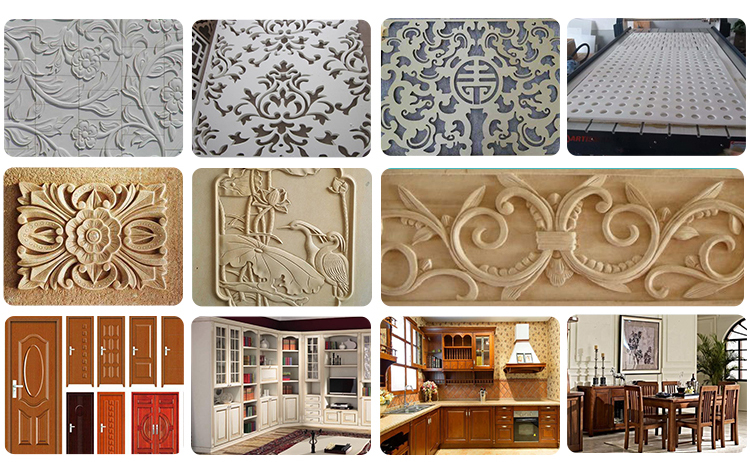

Suitable for all kinds of solid wood, synthetic boards, man-made materials, etc.;

Used in furniture, home improvement, aerospace, mold, advertising, garden engineering, shipbuilding and other industries;

Functions: embossing, lettering, hollowing, cutting, standing carving, round carving, etc.

Model | PT-1325M |

Working area | 1300*2500mm |

Spindle power | 3kw *3 |

Inverter | Fuling |

Drive system | Leadshine servo motor |

Control system | Original Ncstudio |

Max air move speed | 80m/min |

Max working speed | 25m/min |

Reponsitioning accuracy | ±0.05mm |

Vacuum pump | 7.5KW |

Table structure | Vacuum suction |

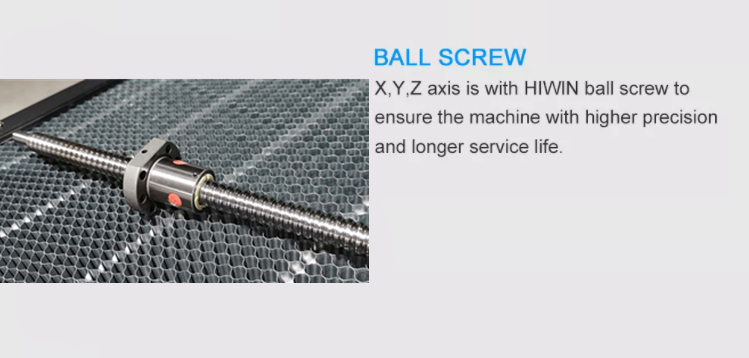

Orbit | Hiwin 20 |

Working Voltage | AC380V/3PH/50Hz |

The high-speed water-cooled frequency conversion motor has low noise, long life and can work continuously for a long time.

2. Adopt square linear slide rail, high-precision ball, dust-proof and vandal-proof slider, strong stability, heavy bearing, high precision, high speed and no abnormal noise. Z-axis screw adopts TBI ball screw, which runs smoothly, smoothly, and has no gap. , The engraving precision is high.

3. The numerical control control system adopts the unique intelligent budget rule to give full play to the potential of the motor, realize high-speed processing, and the curve and straight line are synchronized, and the curve is more perfect.

4. Good software compatibility, compatible with a variety of CAD/CAM design and production software such as type3/Artcam/Castmate/Wentai, and various G code path diagrams.

5. The frame of the whole machine is tempered, and it will not be deformed for 20 years. It is finished by the gantry machining center, and the accuracy of the machine is 0.02mm.