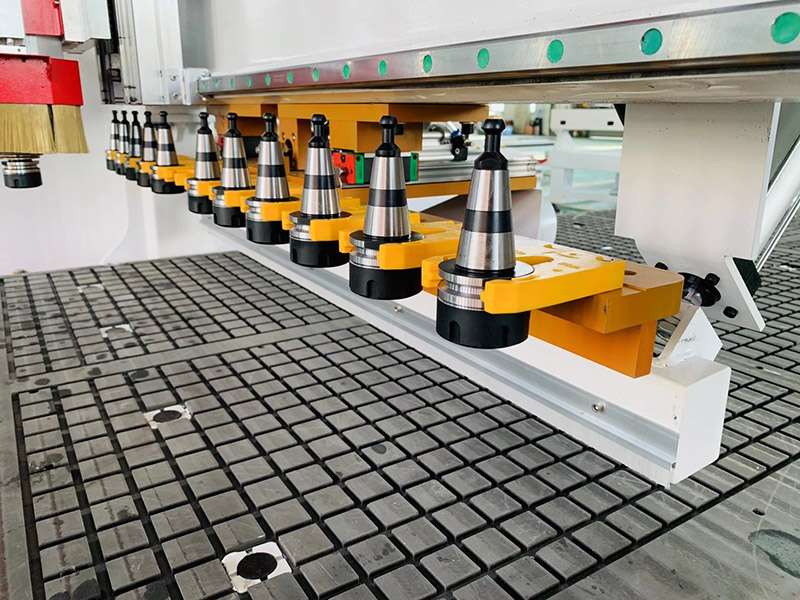

Linear Auto Tools Changer is also widely used in the market. In-line tool change machining center, is that the tool magazine is a fixed row. follow-type in-line tool change can move along with the gantry. The tool change speed is fast, the guide rail wear is small, saving time.

Applicable industries: panel furniture, whole house customization, plastic doors, tables and chairs doors and windows

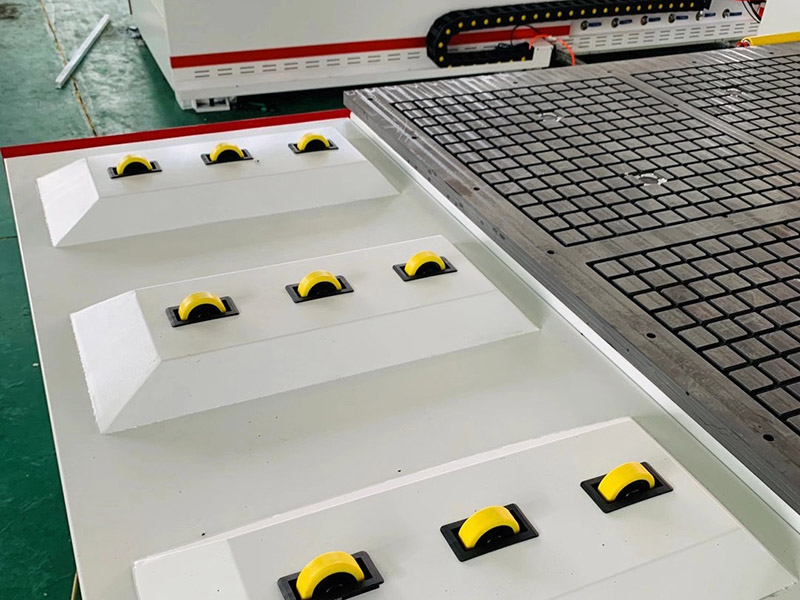

Functions: automatic slotting, automatic reaming, automatic cutting, automatic pushing, automatic tool change

Model | PT-1325L |

Working area | 1300*2500mm |

Spindle power | 9KW ATC |

Inverter | 11KW |

Drive system | Yaskawa |

Control system | Syntec |

Max air move speed | 80m/min |

Max working speed | 25m/min |

Reponsitioning accuracy | ±0.05mm |

Vacuum pump | 7.5KW |

Table structure | Vacuum suction |

Transmission type | Reducer |

Tool Magazine capacity | 12/16/18 |

Dia. of suction port | φ150mm |

Working Voltage | AC380V/3PH/50Hz |

Total power | 28KW(Including vacuum cleaner, vacuum pump) |

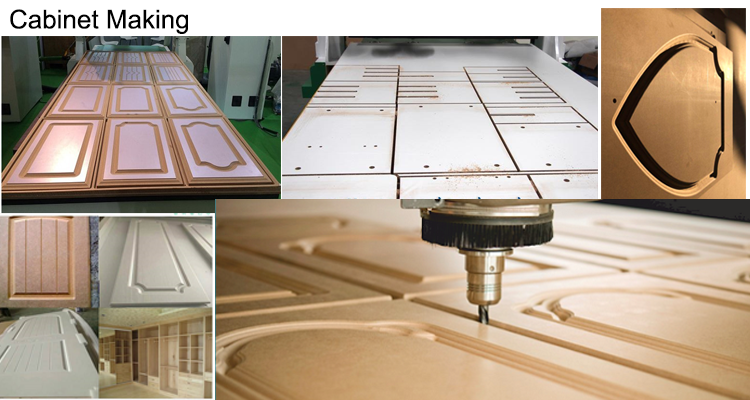

1) Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair,

doors and windows.

2) The wood products: voice box, game cabinets, computer tables, sewing machines

table, instruments.

3) Plate processing: insulation part, plastic chemical components, PCB, inner body

of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other

carbon mixed compounds.

4) Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and

soft metals such as copper, aluminum plate engraving and milling process.