Automatic tool changer (ATC) CNC Router machine is suitable for the processing of various complex products or a variety of processing.

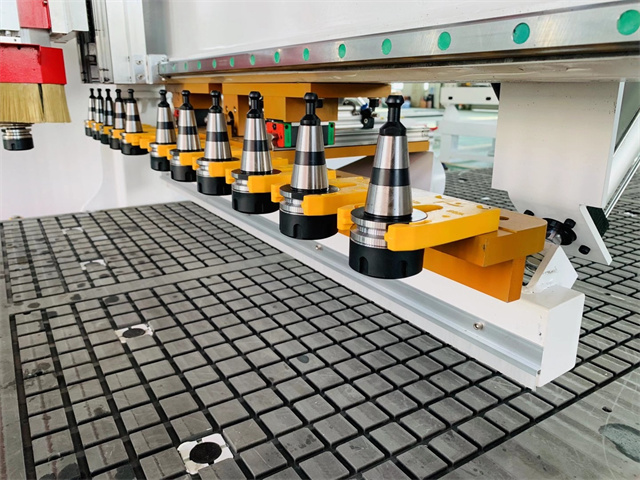

It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers.

There are two tool change modes for inline tool change and disc tool change.

Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

Model | PT-1325 |

Working area | 1300*2500mm |

Spindle power | 9KW ATC |

Inverter | 11KW |

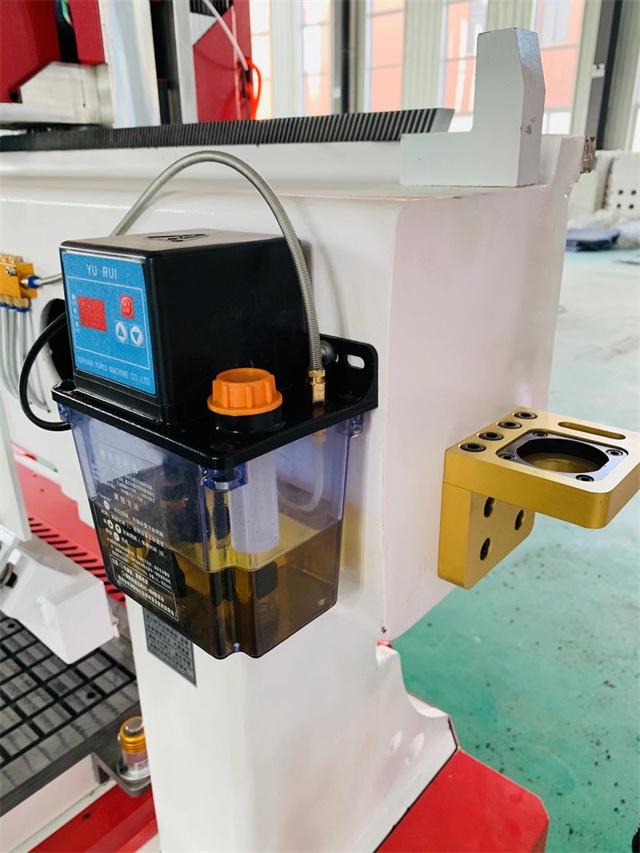

Drive system | Yaskawa |

Control system | Syntec |

Max air move speed | 80m/min |

Max working speed | 25m/min |

Reponsitioning accuracy | ±0.05mm |

Vacuum pump | 7.5KW |

Table structure | Vacuum suction |

Transmission type | Reducer |

Tool Magazine capacity | 12/16/18 |

Dia. of suction port | φ150mm |

Working Voltage | AC380V/3PH/50Hz |

Total power | 28KW(Including vacuum cleaner, vacuum pump) |

♦ It mainly used for woodworking industry, door, cabinets, kitchen utensils, chairs, decoration business, mould industry,wood

panel,wave board processing, MDF sheet carving, screen, calligraphy tablet design , relief, wood furniture, computer tables,

panelfurniture, office furniture,instrument industry, and so on.

♦ It can also for advertising signs, acrylic brands, 3D characters, garden or wall decoration, logo, forming system module,billboard, plate, LED/neon channel, literal-hole cut, blister Light box mold.