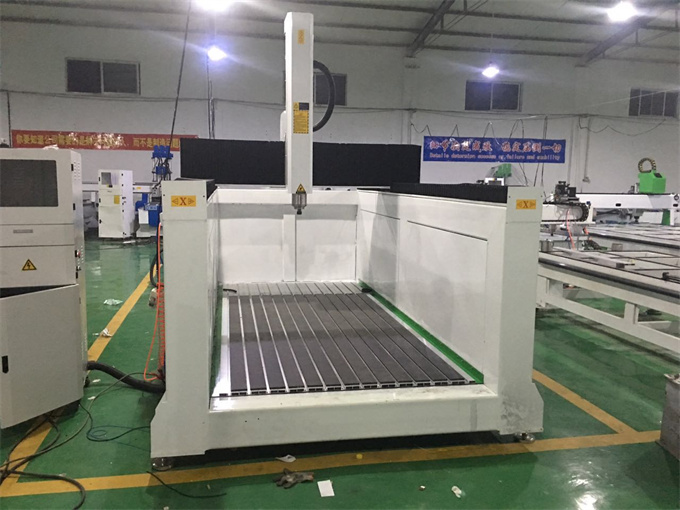

1.The cnc sculpture machine body are professionally welded for wood statue and foam carving.thick steel tubes and VSR processing , no deformation.

2.One machine head or two are optional .

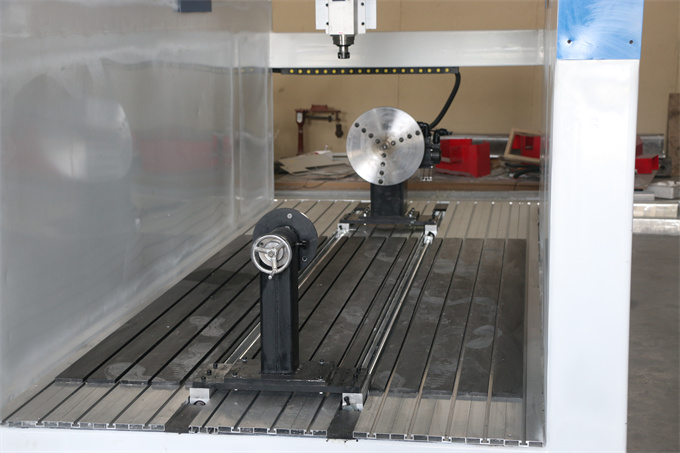

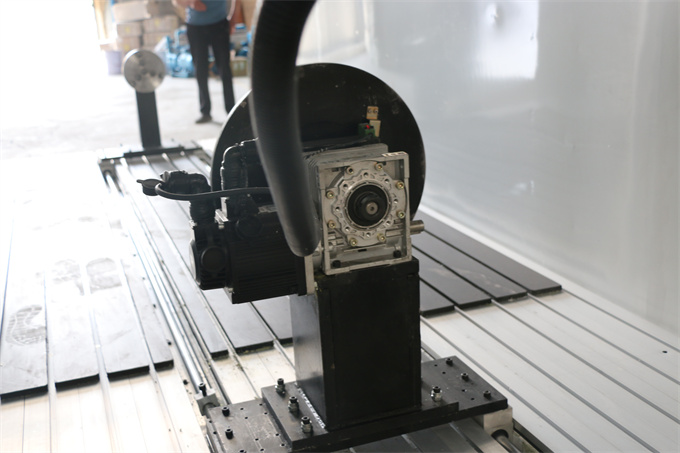

Option: 4 axis and rotary axis are installed for 3d carving

3.spindle are 2.2kw, 3kw 4.5kw, 6kw , air cooling or water cooling spindle

4. X Y Z axis all are equipped with Taiwan Hiwin guide rails, high accuracy and good rigidity.

5. DSP control system with handle , easy to learn and operate.

Machine dimension | 1300mm*2500*800mm | L*W*H |

N.W/G.W | 1400KGS/1500KGS | With control box and package |

Effective working area | 1300*2500mm | |

Z axis working area | 800mm | |

Spindle power | 7.5KW | 4.5 . 6kw optional |

Cooling method | water cooling | |

Spindle speed | 6000-24000rpm | |

Motors | Japan Yaskawa servo motors 750W | Or stepper 450B/Hybrid servo |

Drives | Japan Yaskawa servo drives | |

Inverter | Fuling7.5KW | |

Transmission | TBI Ball screw | X Y Z axes |

Guides rails | Linear TBI square guides | |

Controlling system | DSP control system | Without computer |

Working voltage | 380V | |

Moving method | Gantry moving | |

Table surface | T slot | |

Holding method | By clamps | or vacuum suck |

Machine bed and frame | Steel welded | |

Tools holder and Cutting bits | ER25 | 3.17mm,4mm,6mm,12.7mm |

Software design | Artcam software | English version |

Positioning accuracy | 0.02mm |

wood, styrofoam (EPS), nonmetallic carbonation materials, density board, aluminum,copper, MDF, HDF, PVC, paraffin wax, gypsum,lamp,ceramic,etc.

2D and 3D cutting and carving. wood , foam statue making, door furniture relief carving.