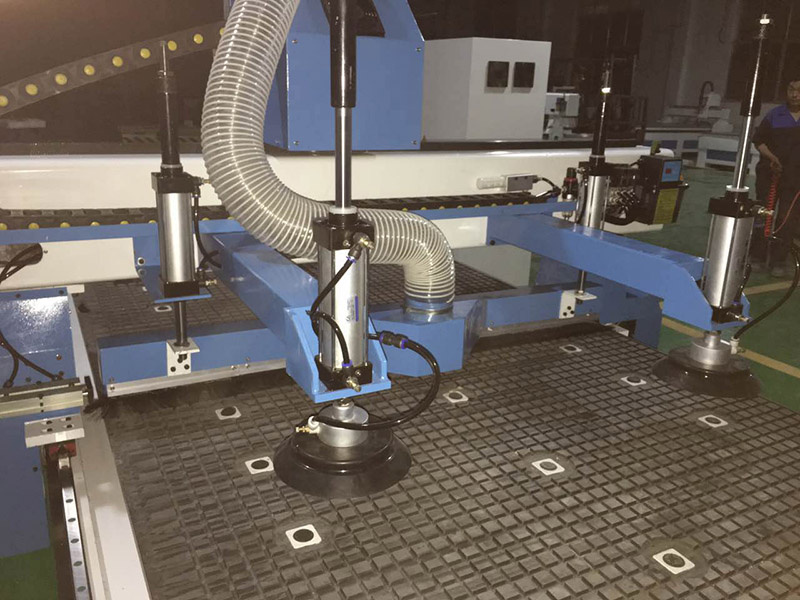

A special machine specialized in cutting and perforating panel custom furniture. It adds a loading platform to get rid of the traditional cutting mode's dependence on labor. The vertical holes are also completed while cutting, which improves efficiency and saves labor.

Model | PT-1325S |

Working area | 1300*2500MM |

Spindle power | 9KW ATC |

Drill | 5+4 |

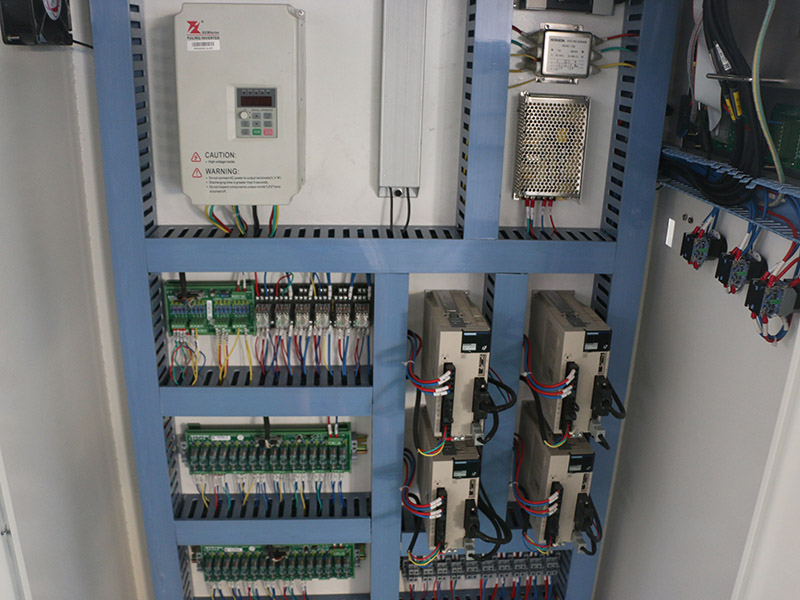

Inverter | 11KW |

Drive system | Yaskawa |

Control system | SYNTEC |

Max air move speed | 80m/min |

Max working speed | 25m/min |

Reponsitioning accuracy | ±0.05mm |

Vacuum pump | 7.5KW |

Table structure | Vacuum suction |

Orbit | PMI |

Transmission type | Reducer |

Tool Magazine Capacity | 12 |

Loading & Unloading Speed | 15m/min |

Working Voltage | AC380V/3PH/50Hz |

Total power | 26KW |

1. 9KW HSD spindle imported from Italy: 12 tools for disc change, meeting the requirements of production technology.

2, 5 + 4 vertical drilling realizes the function of fast drilling, automatic switching during processing, fast speed and high precision.

3. Control system: fast data processing speed, stable operation, simple and intuitive interface, easy to learn;

4. The automatic tool setting function allows users to operate the equipment more conveniently and quickly, while ensuring the accuracy of the equipment.

5. The equipment is equipped with an automatic material pushing function as standard, which can push the plate to the worktable in the front section of the equipment after processing, and has a secondary dust removal function.